centrifugal feeders|bowl feeder manufacturers near me : agent Centrifugal feeders are used by many industries, including pharmaceutical & healthcare, food, plastics as well as Fast-Moving Consumable . See more The autoclave is a sealed device (similar to a pressure cooker) that kills microorganisms using saturated steam under pressure.

{plog:ftitle_list}

With a quick-use design that only takes 3 minutes for a full, sterilized toy to emerge, this sex .

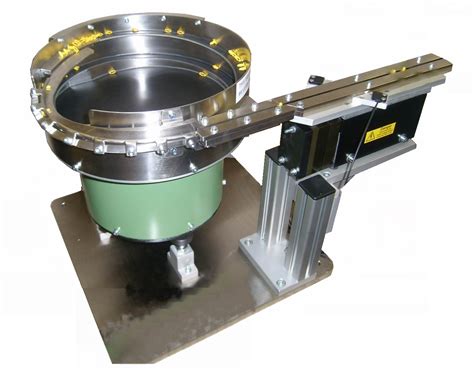

The centrifugal feeder contains a centre disc mounted on an angle and a horizontally mounted feeding bowl. Both parts can rotate independently at variable speeds. The RNA centrifugal feeder can handle up to 3,000 parts per minute. Handled components are usually brought to the raised edge of . See moreCentrifugal feeders are used by many industries, including pharmaceutical & healthcare, food, plastics as well as Fast-Moving Consumable . See more

Benefits of centrifugal feeders include high speed of part processing. Centrifugal feeders are a good alternative to vibratory bowl feeders that can handle up to 3,000 parts per minute . See moreWe would recommend our centrifugal feeder system solutions to businesses in manufacturing, food, pharmaceutical and medical industries where small and awkwardly shaped components need to be handled at high speed. View the range of our case studiesto . See moreHoosier Feeder specializes in delivering high-quality and efficient feeding, orienting, and conveying solutions. Offering custom-built vibratory feeder bowls, centrifugal feeder bowls, .

At Performance Feeders we specialize in using our standard products to design and build custom parts feeding applications to meet your specific needs. We use our line of vibratory feeders, conveyors, centrifugal feeders, step feeders and .Centrifugal Feeders. Centrifugal Feeding Systems. Depending on the type of part and required rate, a centrifugal feeder may fit your needs best. With its angled, double disk design. parts can be discharged at very high rates. The outside disk runs faster than the inside disk so this process creates the centrifugal force that essentially .

Centrifugal feeder systems are designed to ensure manufacturing processes are achieved with a high level of efficiency. Companies in industries such as labelling automation, high-speed packaging, printing, and inspection choose this type .

Centrifugal Feeders & Prefeeders. As a certified dealer and tooling authority for the Shibuya Hoppmann line of centrifugal feeders, Automatic Feeder Company Inc. can provide a system to orient a wide-range of products to meet your requirements. We also offer a series of prefeeders to supply bulk parts to the system at the capacities that fit .Centrifugal feeders are quieter in operation and offer much smoother handling of components, therefore less component damage is caused. The components are fed by the centrifugal disc and distributed onto an outer rim where they are selected and orientated into the required position. They then discharge via the feeder outlet into a gravity .Shibuya Hoppmann’s standard FT-30 rigid disc centrifugal feeder is designed to feed a variety of products with its unique bowl design. Product is metered into the bowl and brought out to the bowl rim where a series of qualifiers gently orient the part for transfer to various downstream inline devices. The FT-30 is our most popular feeder .

Vibratory Feeder bowls and Centrifugal feeders are the foundation of Vibromatic’s vast product line of part handling systems. The name “Vibromatic” is synonymous with vibratory feeder bowls. With over 50 years in the automatic part handling business, Vibromatic has defined, refined, and patented numerous innovations designed to make life .

The patented Hoosier Feeder modular centrifugal feeders drastically reduce the impact of retooling a feeder system by eliminating the need to remove the feeder base from the site. Hoosier Feeder uses a standard feeder base of the correct size to custom makes the new tooling segments that are then shipped to you without the original feeder ever .- Various centrifugal feeder size - Various hopper size - High resolution vision system - High food grade standards Up to 400 products per minute can be sorted for the subsequent packaging process. Meeting .We use vibratory feeding systems (bowl feeder), centrifugal feeders, step feeders, vision and robotics, and step-by-step systems to present the piece in the appropriate position to be introduced into the production process. Feeding systems. Bowl feeders. Feeding systems. Mechanical and Centrifugal feeders. Centrifugal feeders are gentle on component parts due to low circulation and are best suited to high rate applications. How does a centrifugal feeder work? The centrifugal feeder contains a center disc mounted on an angle and a horizontally mounted feeding bowl. Both parts can rotate independently at variable speeds. The centrifugal feeder can .

Centrifugal feeders and OMS part handling and feeding system are offered by Vibrotrac with one goal in mind: they must be fast and they must be reliable. This goal is obtained thanks to innovation such as the patented “Star Wheel” and sensor technology which assures 100% orientation of metal caps and closures at speeds of up to 3,000 parts .

Centrifugal Mechanical Feeders have the same function as Vibratory Feeders, i.e. to create a flow of parts positioned at a given rate, but their driving force is based on the action of an electric motor, generally a three-phase motor which, by means of a combination of gears (reducer) transmits a rotational force to the specific element (plate) which has the task of selecting and .Centrifugal Feeders. The silent, vibration-free centrifugal feeder, also referred to as a rotary feeder, is used to feed components which can be processed at very high speeds. The design features a circular, bowl-shaped wall which surrounds a large rotating disc or plate that is driven by a central motor. The disc can be set at different angles .Centrifugal Feeders may be called many things – unscramblers, rotary bowls, parts sorters, feeder bowls, parts orientors, sorting bowls, feeders – whatever you want to call them, Shibuya Hoppmann’s Centrifugal Feeders get the job done. .

Centrifugal Feeders Overview. Centrifugal Feeders are a type of automation equipment that uses centrifugal force and custom tooling to orient bulk, randomly oriented parts to provide a consistent feed of correctly oriented parts to a .

Our line of standard and scallop centrifugal feeders will provide years of high output parts feeding. Rates as high as 3,000 parts per minute can be sustained with the use of our centrifugal feeders. Delicate Parts Handling – If you need .

Centrifugal feeder systems are used to reduce noise associated with parts feeding systems. They deliver parts at high speeds and are best when feeding a single line. Features and Options. Standard Sizes: Diameters of 15, 20, 30, 40, 50 inches;Service Engineering has been manufacturing the highest quality feeder bowls since 1967. No matter what type of part you need to orient, we have the expertise to build a feeder bowl to exceed your expectations. Rely on a Feeder Bowl Expert.Put your next job in SEI’s hands! .The expert technicians we have at Shibuya Hoppmann build your systems to gently prefeed, unscramble, and orient your product using our state-of-the-art centrifugal feeder systems. Our many years of experience designing and engineering have taught us how to create a feeding solution for virtually any part quickly and efficiently.

Shibuya Hoppmann’s standard FT-20-RD centrifugal feeder is designed using a rigid disc to feed a variety of products with its unique bowl design. Product is metered into the bowl and brought out to the bowl rim where a series of qualifiers gently orient the part for transfer to various downstream inline devices. This system varies in feed .Reliable, high-speed part handling. Hoosier Feeder centrifugal feeder bowls are designed and built by our experienced team to give you the most reliable feeding system possible. Our standard rotary parts handling systems can be tooled for an incredible range of parts, from large-diameter lids to disposable coffee pods and candy bars.Service Engineering designs, manufactures, refurbishes and services custom rotary bowls and centrifugal feeder systems as well as vibratory feeder bowls. Trust us with your parts feeding project. - Greenfield, Indiana

SWOER specializes in delivering high-quality and efficient feeding, orienting, and conveying solutions. As China’s TOP 3 vibratory feeder supplier, we offer custom-built vibratory bowls feeder , centrifugal feeder, flexible feeder systems, and more, proudly serving industries worldwide with dependable automation equipment.The bowl feeder, including an out feed accumulation track to convey parts along and discharge into the assembly machine are supplied in many shapes and sizes. The drive unit, available in both electromagnetic and pneumatic drives, vibrates the bowl feeder, forcing the parts to move up a circular, inclined track. Centrifugal feeders also referred as 'rotary feeders', have a conical central driven rotor surrounded by a circular bowl wall. The feeder separate component parts utilizing rotary force and the .

vibratory feeder with hopper

This short video demonstrates a vertical elevating prefeeder and high speed gravity roller tracks, this centrifugal feed system was developed to feed and orient medical product in excess of 800 ppm and built to run 24/7 in a continuous production environment, while using the smallest footprint possible and preserving the integrity of the parts being fed.

how to calibrate a veterinary refractometer

how to calibrate a veterinary refractometer schaco

An autoclave can be defined as an instrument used to clean any equipment and keep germs and bacteria-free. It is used in Laboratories, data centers, research centers, pharmaceuticals giants, educational institutes, .

centrifugal feeders|bowl feeder manufacturers near me